iron grinding mill

Iron Ore Processing: From Extraction to

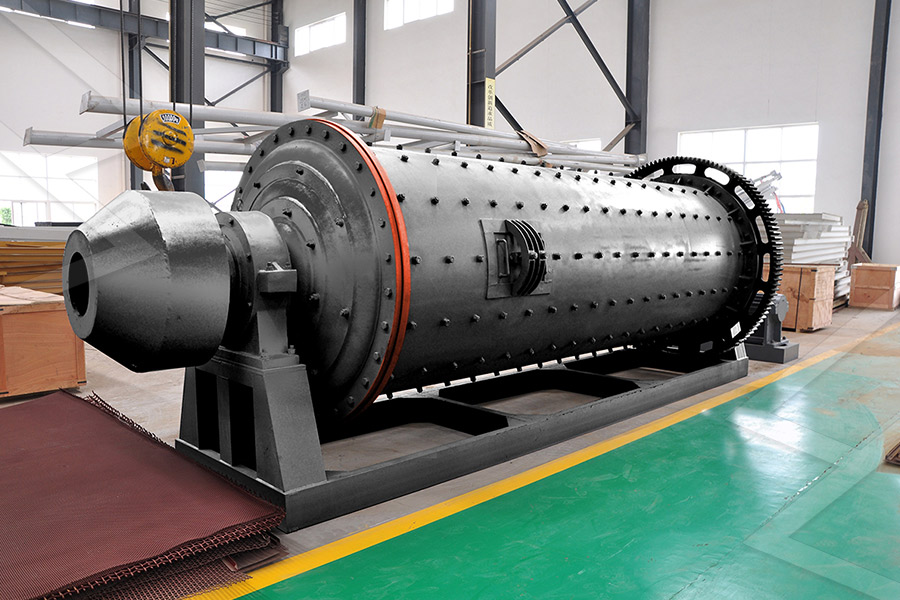

2024年4月26日 Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Grinding within a tumbling mill is influenced by the size, quantity, the type of motion, and the spaces between the individual pieces of the medium in the mill As opposed to crushing, which Grinding Mill an overview ScienceDirect Topics2022年3月30日 Currently Autogenous (AG)/SemiAutogenous (SAG)/Ball mill technology dominates comminution circuit design where grinding to relatively fine sizes is required, eg the Helping to reduce mining industry carbon emissions: A step

Ore Grinding SpringerLink

2023年7月20日 Ore grinding is completed in the cylinder of the grinding mill With a certain amount of grinding medium in the cylinder, when the cylinder rotates, the grinding medium is 2021年11月1日 The present work analyzes the application of the UFRJ mechanistic ball mill model to grinding of iron ore pellet feed in an industrial grinding circuit In order to address the Mechanistic modeling and simulation of grinding iron ore Iron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of Iron ore grinding mill Grinding plants for Iron Ore2020年3月28日 Modern iron ore pelletizing process operations may be divided into two main process sections: feedstock preparation and agglomeration processes In most plants, the Development of a Novel Grinding Process to Iron Ore

Grinding iron ore concentrate by using HPGR and ball mills

2022年3月19日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of 2 天之前 Stirred milling was developed for fine grained ores that required an economic grind to sub 10 micron sizes The first examples were lead zinc deposits – McArthur River, George Fine Grinding as Enabling Technology – The IsaMill2023年5月2日 The mill comes with a limited lifetime warranty from Victoria, covering craftsmanship defects for life from the date of purchase The Victoria is an economical hand mill best suited for grinding dry grains and legumes into The Best Countertop Grain Mills and Flour 2 天之前 Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel mill with very small balls, the amount of iron in solution would almost certainly ruin downstreamFine Grinding as Enabling Technology – The IsaMill

.jpg)

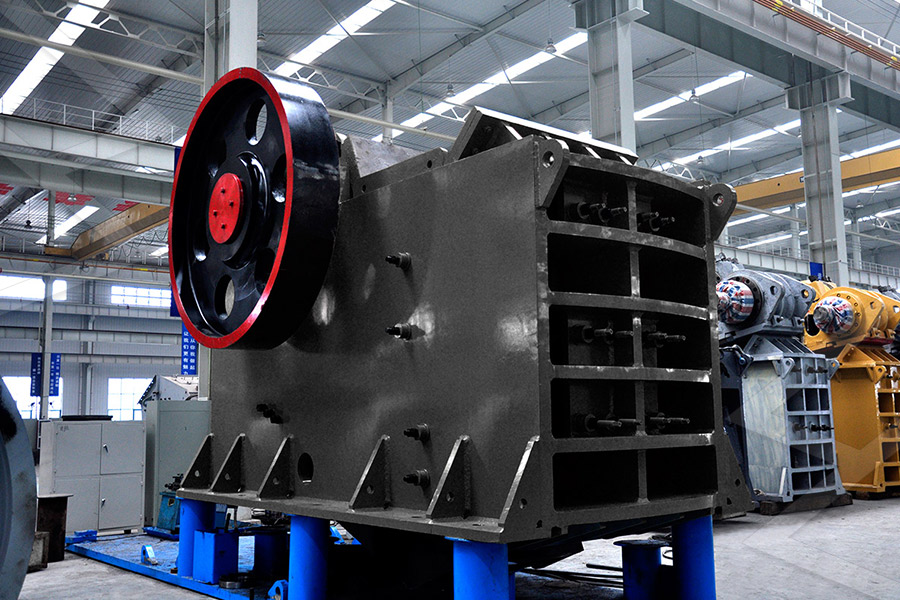

Grinding Mill Design Ball Mill Manufacturer

2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material spherical shaped grinding media is termed ball milling Strictly speaking, such media are made of steel or iron When iron contamination is detrimental, porcelain or natural nonmetallic They are widely employed in both wet and dry grinding processes for the comminution of materials such as gold, copper, iron, and leadzinc ores Pharmaceutical Industry: Ball mills are utilized in the pharmaceutical industry for size reduction and mixing of active pharmaceutical ingredients (APIs) and excipients Ball mill grinding machines Ball Mill Grinding Machines: Working Principle, Types, Parts 2024年5月6日 A crucial step in mineral processing – and in Minnesota’s iron ore processing – is comminution, a process of crushing and grinding Large rocks must first be crushed and then ground down to tiny particles to expose the valuable or desired minerals so they can be separated from the waste rock The prevalence of lowgrade and complex ores make fine and ultrafine NRRI advances efficient grinding technology on the Iron RangeGrinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the kWhr per ton ground When the material exits the mill, the iron ore is classified using The six main steps of iron ore processing Multotec

.jpg)

Grinding Mills 911Metallurgist

3 天之前 Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill 2 天之前 How to Assemble and use a Victoria Cast Iron Grain Grinder Mill 9 Cast Iron Crank Manual Grain Mill Buy on Amazon This grain miller is very sturdy, and it can grind any seeds or seeds you want very fine The fine level of the seeds can be adjusted by applying harder grind through the pressure of your hand To avoid getting metal 15 Best Manual Grain Mills or Ginders in 2023 Economical 2022年1月1日 The mill is filled with suitable grinding media, and the space between each of the disks is essentially an individual grinding chamber As a result, the mill effectively comprises eight grinding chambers in series The media is set in motion by the action of the grinding disks, which accelerate the media nearby radially toward the minution and classification technologies of iron ore2024年3月19日 This grain mill is a large grinder with a 2lb hopper to ground a good amount of flour The grinder is aluminum cast and resistant to rust corrosion In addition, there are two ball bearings for the specific grinding instead of bushings used by other manufacturers The grinder offers an adjustable level of how fine flour you want5 Best Manual Grain Mills For Freshly Ground Flour Build a

.jpg)

Corona Cast Iron Corn and Grain Mill with

Amazon: Corona Cast Iron Corn and Grain Mill with Wooden Table, Corn Grinder, Grain Mill, Manual Grinder with Table For Corn, Rice, Lentils, Chickpeas, Cast Iron Grinder For Domestic Use, AntiRust By Corona : Home Kitchen2024年9月26日 Energy savings and consumption reduction of ball mills are crucial for industrial production The grinding medium is an important component of a ball mill In theory, using higherdensity grinding media can yield better grinding results However, for materials with varying grindability, employing grinding media of different densities can reduce energy consumption Optimization and Experimental Study of Iron Ore Grinding The group company consists of Jinan Huafu Forging Co,Ltd,Shandong Huafu Steel Ball Co,Ltd and Jinan Xing Tigers of Papermaking Machinery Co,LtdWe mainly produces forged steel balls, cast iron balls, steel cylpebs, grinding rods, mill liners, steel, hammer heads, automatic production lines for steel balls grinding rods, decorative wrought Jinan Huafu Forging JointStock Co, Ltd2021年11月1日 The present work analyzes the application of the UFRJ mechanistic ball mill model to grinding of iron ore pellet feed in an industrial grinding circuit In order to address the challenge of applying the model to a reasonably fine feed, selected model parameters were backcalculated on the basis of batch grinding tests The model is then used to Mechanistic modeling and simulation of grinding iron ore

.jpg)

Balls, iron/steel, forged/stamped for grinding mills

In 2022, Balls, iron/steel, forged/stamped for grinding mills were the world's 1664th most traded product, with a total trade of $167B Between 2021 and 2022 the exports of Balls, iron/steel, forged/stamped for grinding mills grew by 259%, from $133B to $167B Trade in Balls, iron/steel, forged/stamped for grinding mills represent 00071% 2015年3月15日 Regarding the first abovementioned issue facing labscale grinding research, Hardgrove mill or labscale roller mill were applied to simulate the grinding process of particles in industrial Research of iron ore grinding in a verticalrollermillGrinding is much easier and more fun with two people Bushing/sealed bearings eliminate maintenance never need to be oiled! Built to last This mill hearkens to an earlier time when things were built to outlast their owner and be passed on to the next generation Solid cast iron mill is one of the heaviest hand mills in the worldDiamant CastIron Manual Grain Mill Extreme Wellness 2013年8月1日 Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 rpm for 1 hrConsumption of steel grinding media in mills – A review

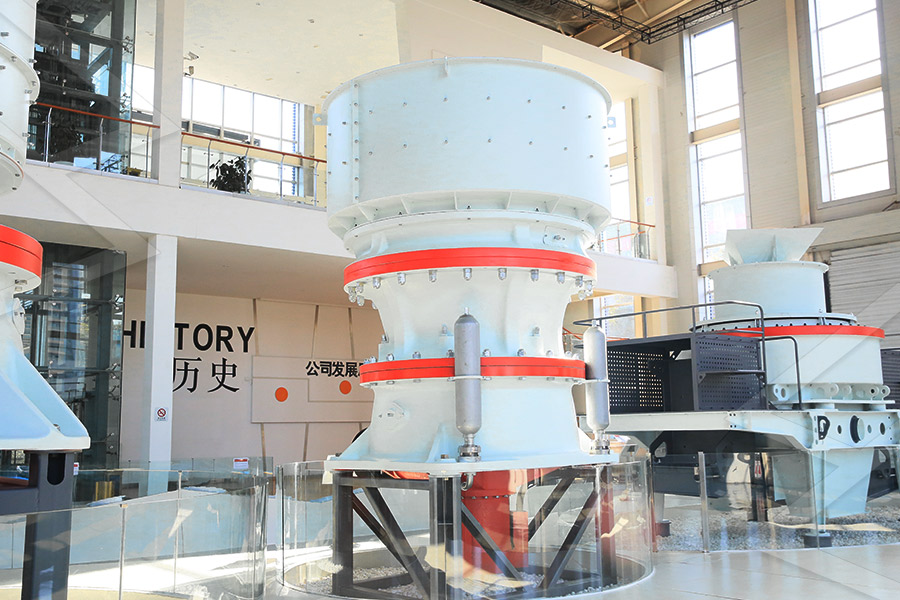

Iron ore grinding mill Grinding plants for Iron Ore

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing But the degree of largescale is relatively lower compared to vertical grinding mill 2, HLM vertical mill: largescale equipment, high capacity, to meet the largescale production 2024年6月19日 The F4 grinding mill head can be easily disassembled for cleaning without the use of any special tools The grinding plates are made of a hard iron alloy designed for clog resistance and long life A new optional Model 4F Hand Mill Quaker City Grinding Mills 2021年11月1日 Comparative grinding tests are done by using cast iron segment steel ball Grinding test results showed that mill capacity and grinding efficiency of cast iron segment could be really superior to Morphology and wear of high chromium and austempered ductile iron 2024年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate

.jpg)

How to pick the best home grain mill: A buyer's guide for

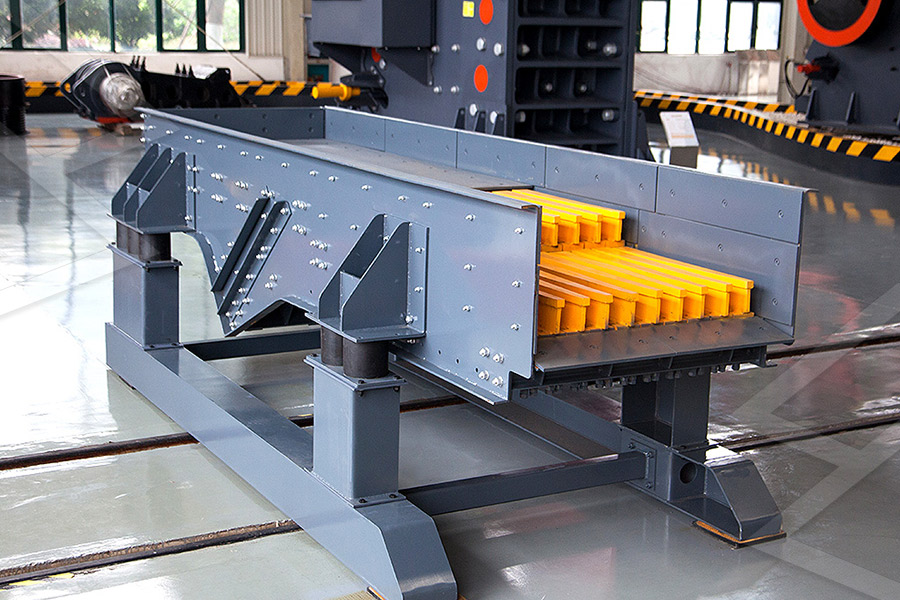

2024年2月12日 Cast Iron: Durable, consistent grind, requires maintenance to prevent rust Steel/Stainless Steel: Lightweight, rustresistant, durable Stone: Ideal for fine flours, heavier, may wear over time Some mills grind grains faster than others, and I need to decide whether speed is a high priority for me A faster mill might save me time but 2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection Population balance model approach to ball mill optimization in iron 2015年3月15日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Research of iron ore grinding in a verticalrollermill2015年4月9日 Very fine grinding mills The following are the mills used for very fine grinding Hammer mills Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm A set of ‘hammers’ rotate about a central axis in a vertical or horizontal plane The hammers are either be fixed or are swinging freelyGrinding Mills and Their Types IspatGuru

Corona® Hand Mill for Grains Beans

The Corona ® Hand Mill for Grains Beans Chefs, bakers, and brewers are raving about The Corona ® Mill! The Corona ® Mill is manufactured in Colombia and has been used for years in South American kitchens This sturdy, dependable grinder is made out of the finest quality castiron, guaranteeing a long lifeStep back in time with the Premium Quality Cast Iron Corn Grinder, a perfect flour mill grinder for home use This wheat mill grinder for home use pays homage to the ageold methods of grain processing, providing a unique, handson experience Showcasing a large top capacity, this manual grain mill can accommodate a significant amount of grainsPremium Quality Cast Iron Corn Grinder For Wheat Grains Or 2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in Grinding Mills — Types, Working Principle Applications2023年5月2日 The mill comes with a limited lifetime warranty from Victoria, covering craftsmanship defects for life from the date of purchase The Victoria is an economical hand mill best suited for grinding dry grains and legumes into The Best Countertop Grain Mills and Flour

Fine Grinding as Enabling Technology – The IsaMill

2 天之前 Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel mill with very small balls, the amount of iron in solution would almost certainly ruin downstream2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material spherical shaped grinding media is termed ball milling Strictly speaking, such media are made of steel or iron When iron contamination is detrimental, porcelain or natural nonmetallic Grinding Mill Design Ball Mill ManufacturerThey are widely employed in both wet and dry grinding processes for the comminution of materials such as gold, copper, iron, and leadzinc ores Pharmaceutical Industry: Ball mills are utilized in the pharmaceutical industry for size reduction and mixing of active pharmaceutical ingredients (APIs) and excipients Ball mill grinding machines Ball Mill Grinding Machines: Working Principle, Types, Parts 2024年5月6日 A crucial step in mineral processing – and in Minnesota’s iron ore processing – is comminution, a process of crushing and grinding Large rocks must first be crushed and then ground down to tiny particles to expose the valuable or desired minerals so they can be separated from the waste rock The prevalence of lowgrade and complex ores make fine and ultrafine NRRI advances efficient grinding technology on the Iron Range

The six main steps of iron ore processing Multotec

Grinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the kWhr per ton ground When the material exits the mill, the iron ore is classified using 3 天之前 Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill Grinding Mills 911Metallurgist2 天之前 How to Assemble and use a Victoria Cast Iron Grain Grinder Mill 9 Cast Iron Crank Manual Grain Mill Buy on Amazon This grain miller is very sturdy, and it can grind any seeds or seeds you want very fine The fine level of the seeds can be adjusted by applying harder grind through the pressure of your hand To avoid getting metal 15 Best Manual Grain Mills or Ginders in 2023 Economical 2022年1月1日 The mill is filled with suitable grinding media, and the space between each of the disks is essentially an individual grinding chamber As a result, the mill effectively comprises eight grinding chambers in series The media is set in motion by the action of the grinding disks, which accelerate the media nearby radially toward the minution and classification technologies of iron ore

.jpg)

5 Best Manual Grain Mills For Freshly Ground Flour Build a

2024年3月19日 This grain mill is a large grinder with a 2lb hopper to ground a good amount of flour The grinder is aluminum cast and resistant to rust corrosion In addition, there are two ball bearings for the specific grinding instead of bushings used by other manufacturers The grinder offers an adjustable level of how fine flour you want